SMART FACTORY

Connected technologies that drive P&L and ESG impact on the plant floor

Supply chain kinks, global inflation, rising geopolitical tension, chip shortages, tight labor conditions – it all adds up to a giant dose of uncertainty. As companies experience wave after wave of disruption, nearshoring is on the minds of many manufacturing executives. Coupled with government incentives for some industries, such as semiconductor manufacturing in the U.S., adapting a “build where we sell” approach is becoming more attractive.

To compete and make reshoring viable, North American manufacturers need to outpace the rest of the world in digitalizing their plant floors in order to exponentially increase labor productivity in a market with ever-increasing labor costs.

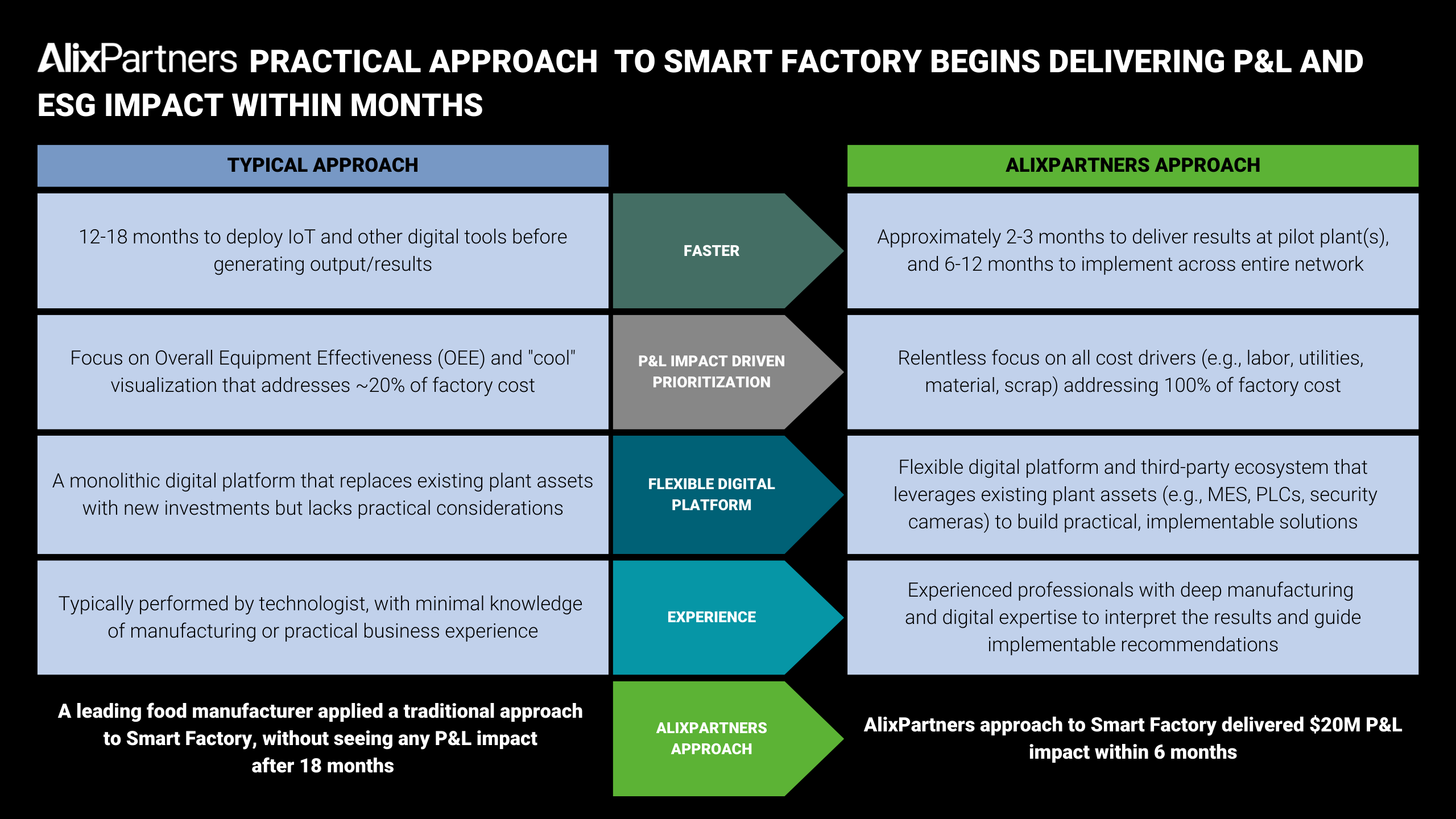

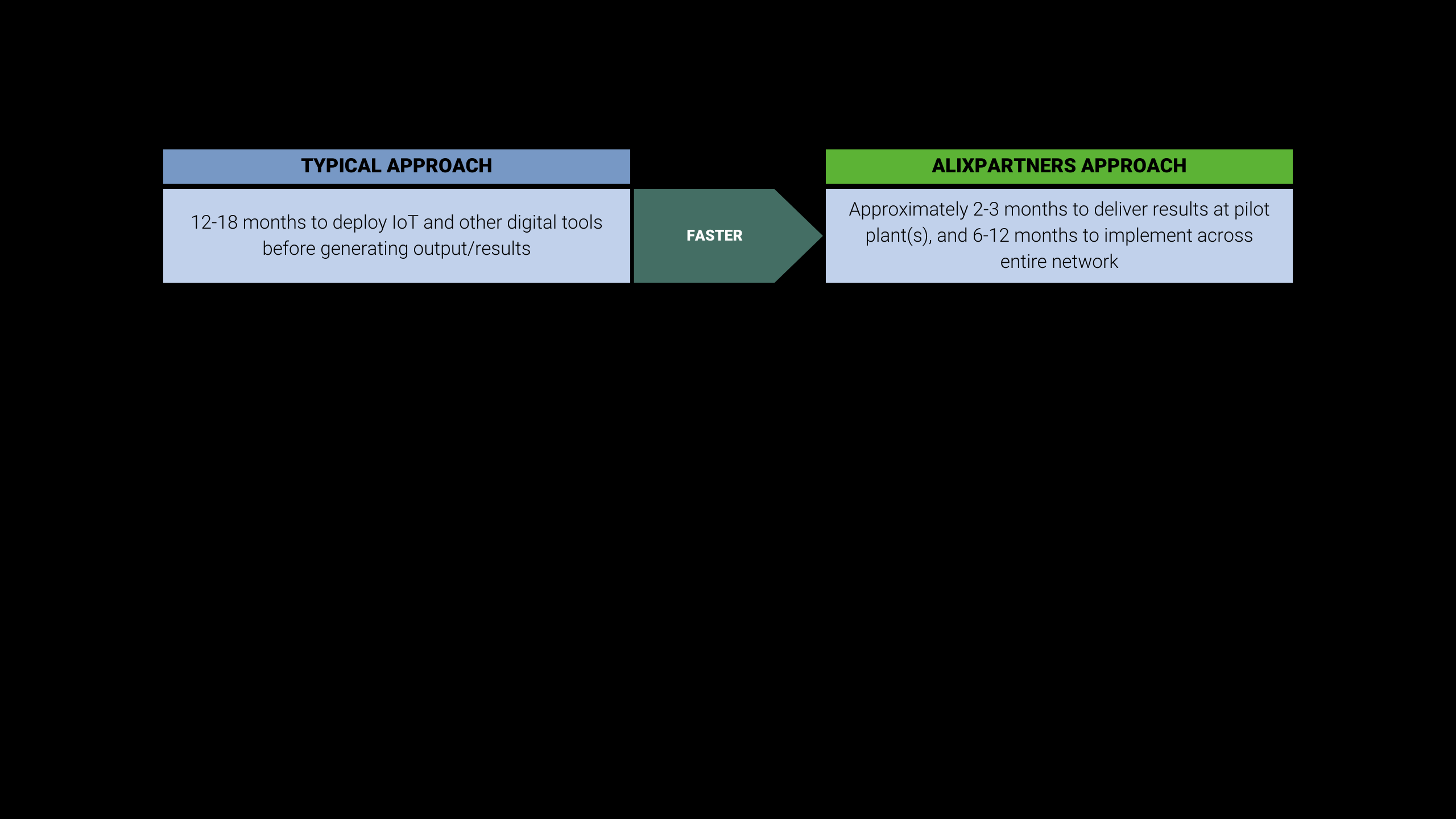

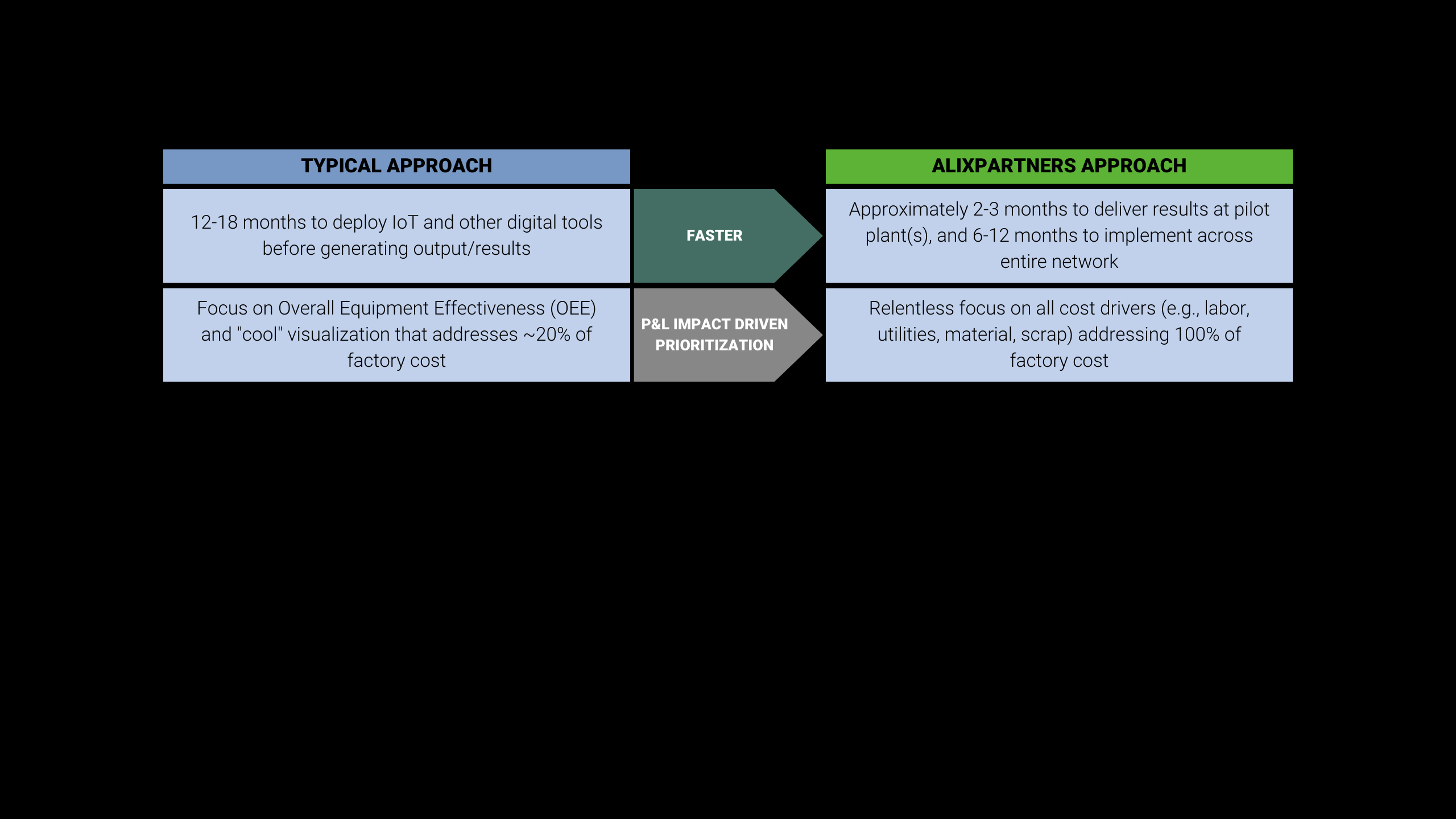

In our experience, no matter the scale and sophistication of the tools that enable a smart factory, they need to be deployed with a profit-and-loss (P&L) centric approach. Pragmatism is required for success on the plant floor.

Supply chain kinks, global inflation, rising geopolitical tension, chip shortages, tight labor conditions – it all adds up to a giant dose of uncertainty. As companies experience wave after wave of disruption, nearshoring is on the minds of many manufacturing executives. Coupled with government incentives for some industries, such as semiconductor manufacturing in the U.S., adapting a “build where we sell” approach is becoming more attractive.

To compete and make reshoring viable, North American manufacturers need to outpace the rest of the world in digitalizing their plant floors in order to exponentially increase labor productivity in a market with ever-increasing labor costs.

In our experience, no matter the scale and sophistication of the tools that enable a smart factory, they need to be deployed with a profit-and-loss (P&L) centric approach. Pragmatism is required for success on the plant floor.

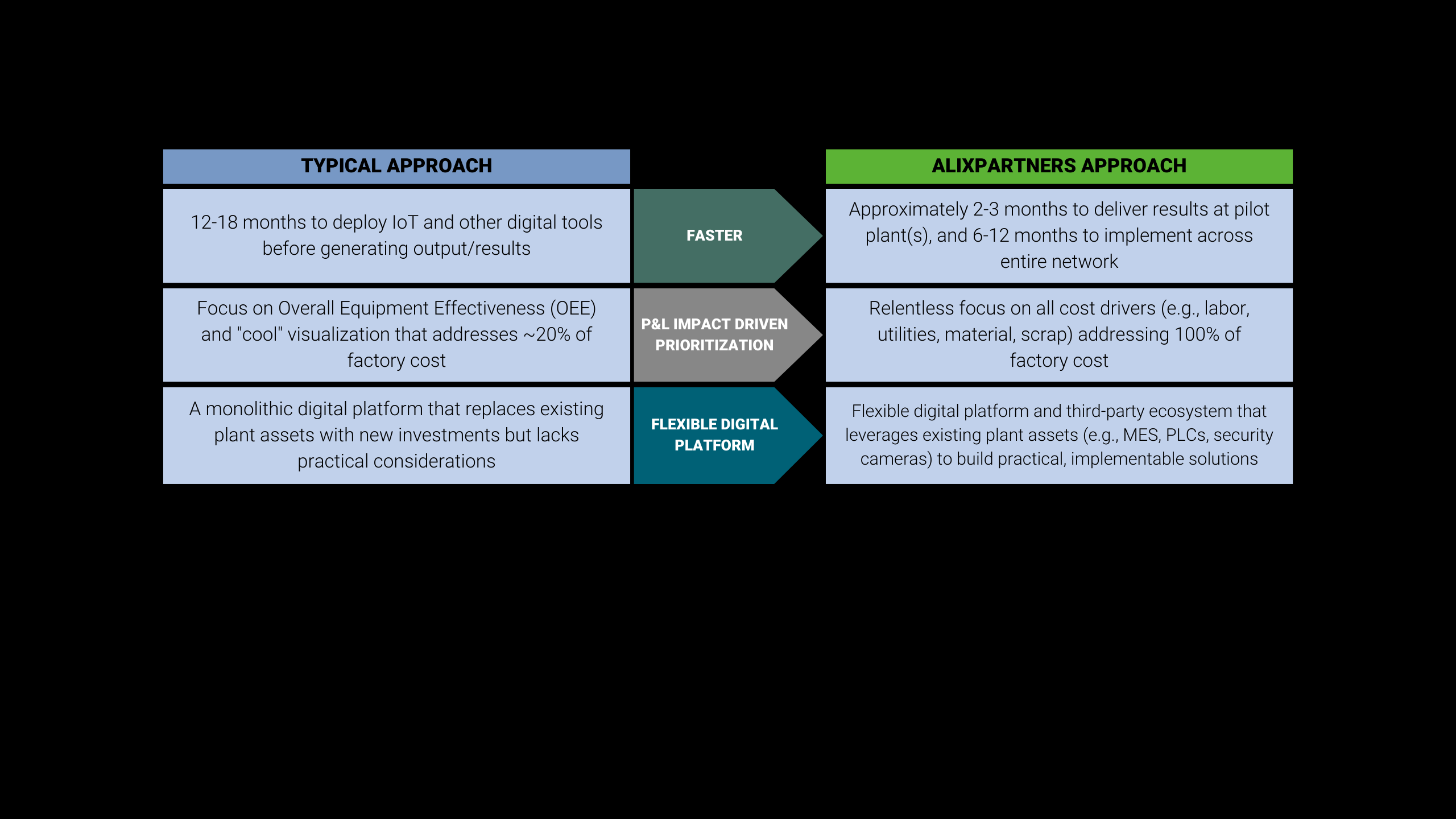

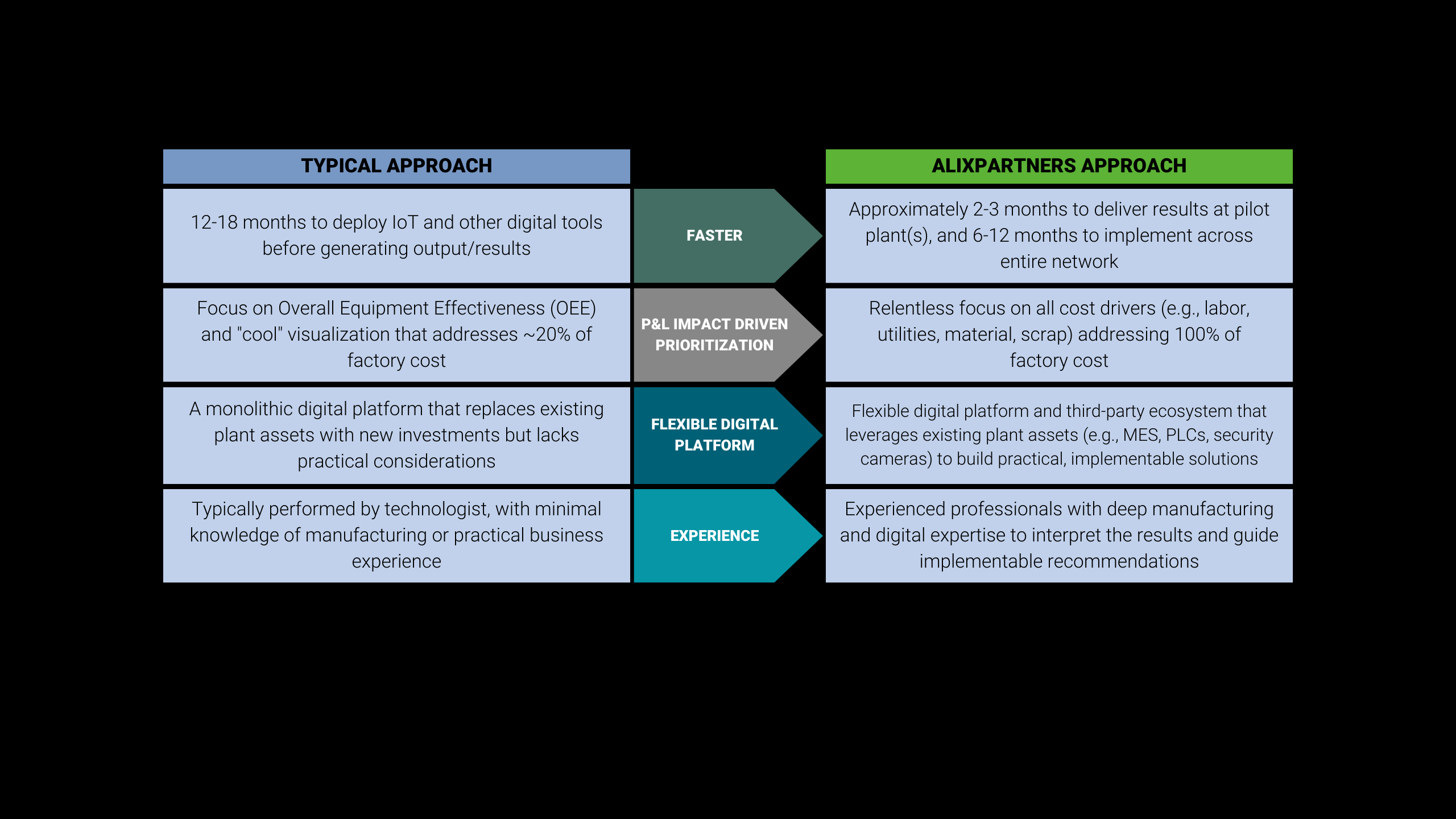

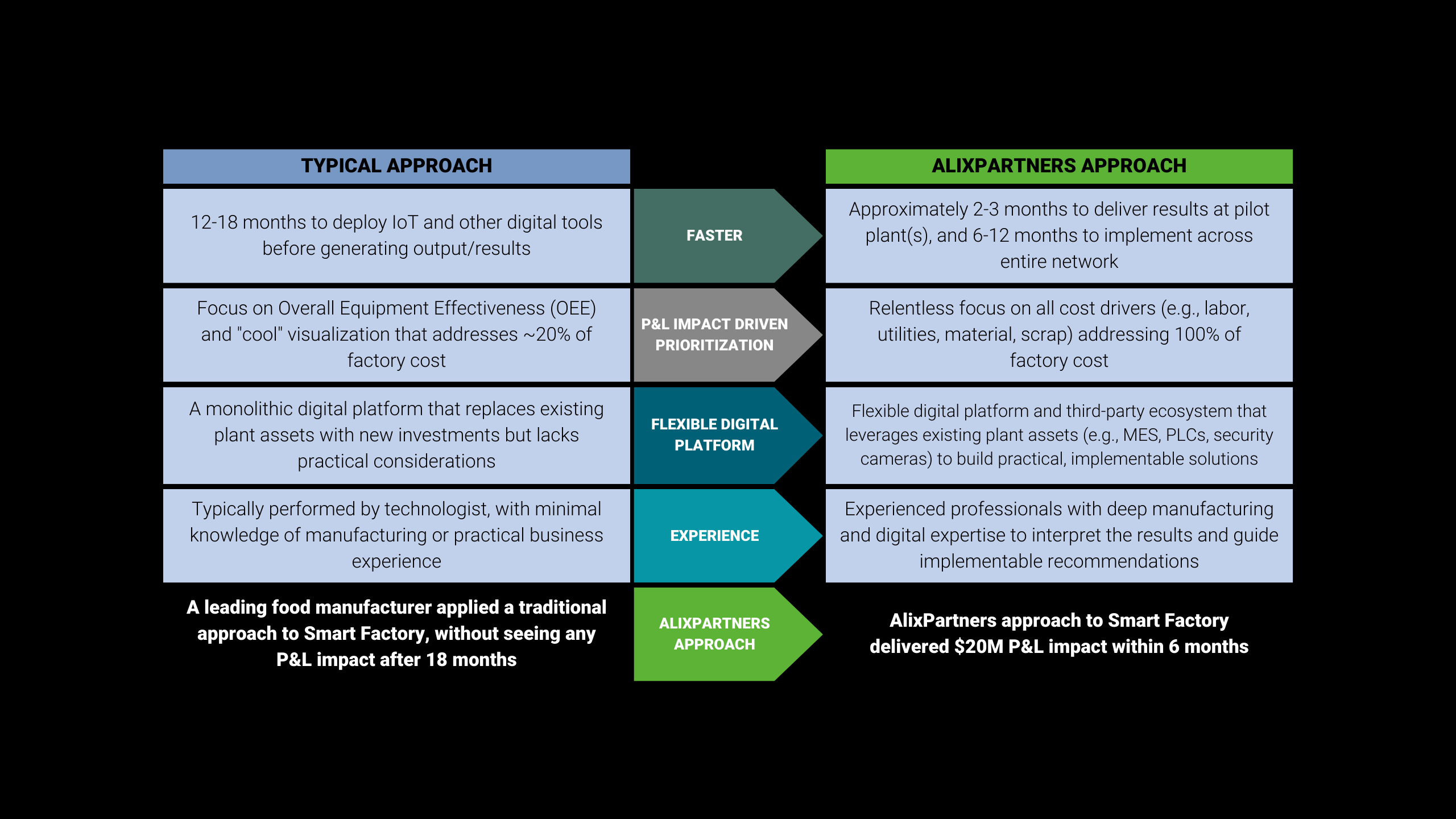

Sensible implementation is a hallmark of our approach

We help companies quickly deploy next-generation technologies across their manufacturing network to increase productivity, reduce waste and drive significant savings. By following a practical approach, targeted Smart Factory investments can provide significant productivity to the factory floor in a matter of months, not years.

Meet our global Smart Factory leadership team:

Our team of experts bring decades of experience running factory floor operations combined with deep knowledge of digital implementation to develop a P&L-focused solution to enable cost-effective reshoring and tame the disruptive forces at work.

More insights from our experts

Transforming the factory

Business transformation and innovation could be the two most popular ideas floating around the business world today. They’re also on the minds of manufacturing professionals. That’s because transformation doesn’t end in the C-suite. It’s happening every day on the factory floor, driven by a host of external pressures and enabled by the emergence of digital NextGen technologies.

How Off-the-Shelf Tech Can Make Factories More Profitable

Too often, smaller companies are intimidated by the high costs, complexity, and long installation times that high-end smart factory systems can require. This is short-sighted. Companies can see big financial benefits by utilizing existing data and simpler technologies to reduce waste, labor costs, overhead, and utility expenses.

A factory "digital twin" can deliver bottom-line benefits in as little as four weeks

Some of my clients think that the Internet of Things (IoT), "smart factories", and "digital twins" are technologies for companies ready to spend tens of millions over years. As described by The Wall Street Journal, the experience of Unilever proves otherwise.

Shifts in the global supply chain and the impact on nearshoring

The factors driving the business case for companies to participate in nearshoring are becoming clear, consistent, and far-reaching. The number of industries affected by it will expand as the ecosystem evolves. However, a solid strategy, effective tools, and comprehensive real-time analysis will still be needed.

Reshoring is on the rise;

how smart is your

factory?

Disruption has become a constant fixture for anyone in business leadership, particularly those in manufacturing. Supply chain kinks, global inflation, rising geopolitical tension, chip shortages, tight labor conditions – it all adds up to a giant dose of uncertainty.

Labor productivity, automation, and the case for digital manufacturing

Supply chains are vast and complex. With the need for semi-conductors and rare earth metals, and the country’s deep consumer markets, the likelihood of reducing economic dependence on China seems unlikely. But as labor costs in the People’s Republic have increased, manufacturers are searching for the next fruitful labor market.

Smart factories: Easy-to-implement technology can have a rapid impact on your P&L

Following the well-documented supply chain meltdowns we’ve seen over the last few years, it is only natural that many companies are looking for ways to bring their manufacturing operations closer to home or the regions they serve through nearshoring or reshoring.

New York (Headquarters)

909 Third Avenue

New York, NY 10022

O +1 212 490 2500

F +1 212 490 1344

Connect with the experts behind the results.

Contact us if you would like to learn more about your practical approach to Smart Factory and how we can help achieve P&L impact on your factory floor.